Moulds Construction

From design to construction, Uniplast entirely produces the molds in its workshop: on average, we finalize 70 new molds every year, to which we add the processes such as set-ups and modifications.

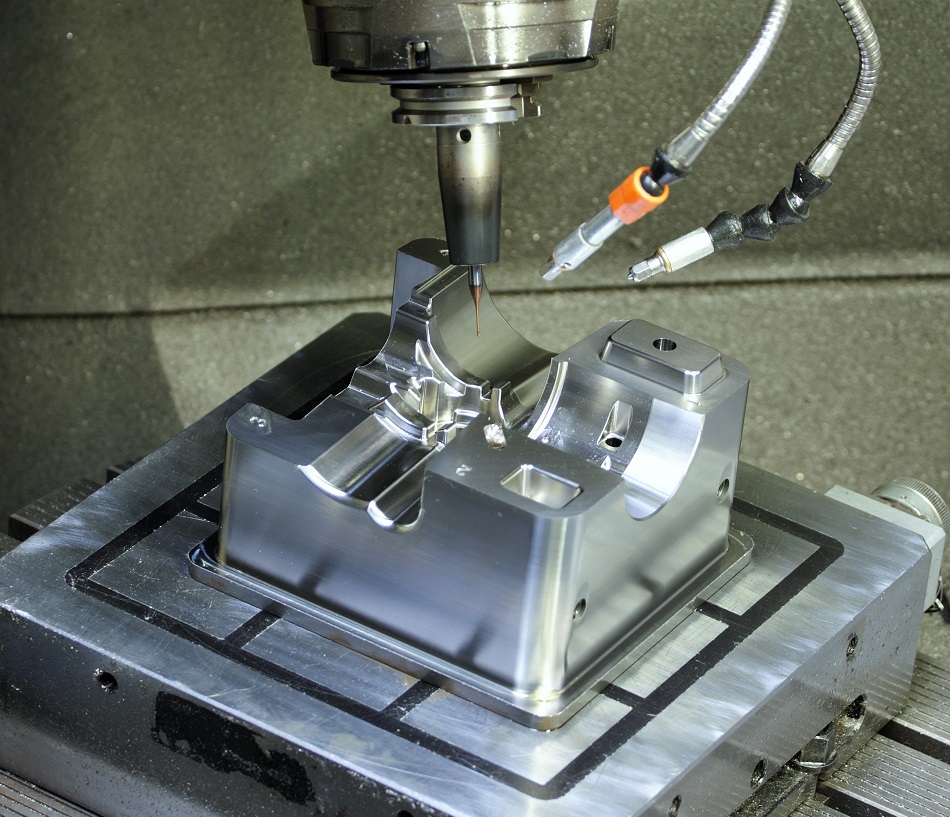

Following the realization of the mathematics of all the elements that make up the project, we proceed to the processing of CAM machine paths using HSC 3-4-5 simultaneous axes, EDM and WEDM technologies.

Thanks to path simulators, we move on to the analysis of production processes to obtain an optimization both in terms of quality and of processing times.

Uniplast pays the utmost attention to the choice of materials and treatments to be applied in the manufacture of equipment, bearing in mind the needs that must be met by the equipment during its lifetime.

Our molds workshop is equipped with 6 CNC machines with 3-4-5 axes, 3 EDM CNC and 2 WEDM, 1 Laser Welder and 2 Lathes, as well as a 3D prototyping machine SLA technology.